The Industrial Internet of Things (IIoT) and the Panels of the Future

By Evan Coulter

Evan Coulter

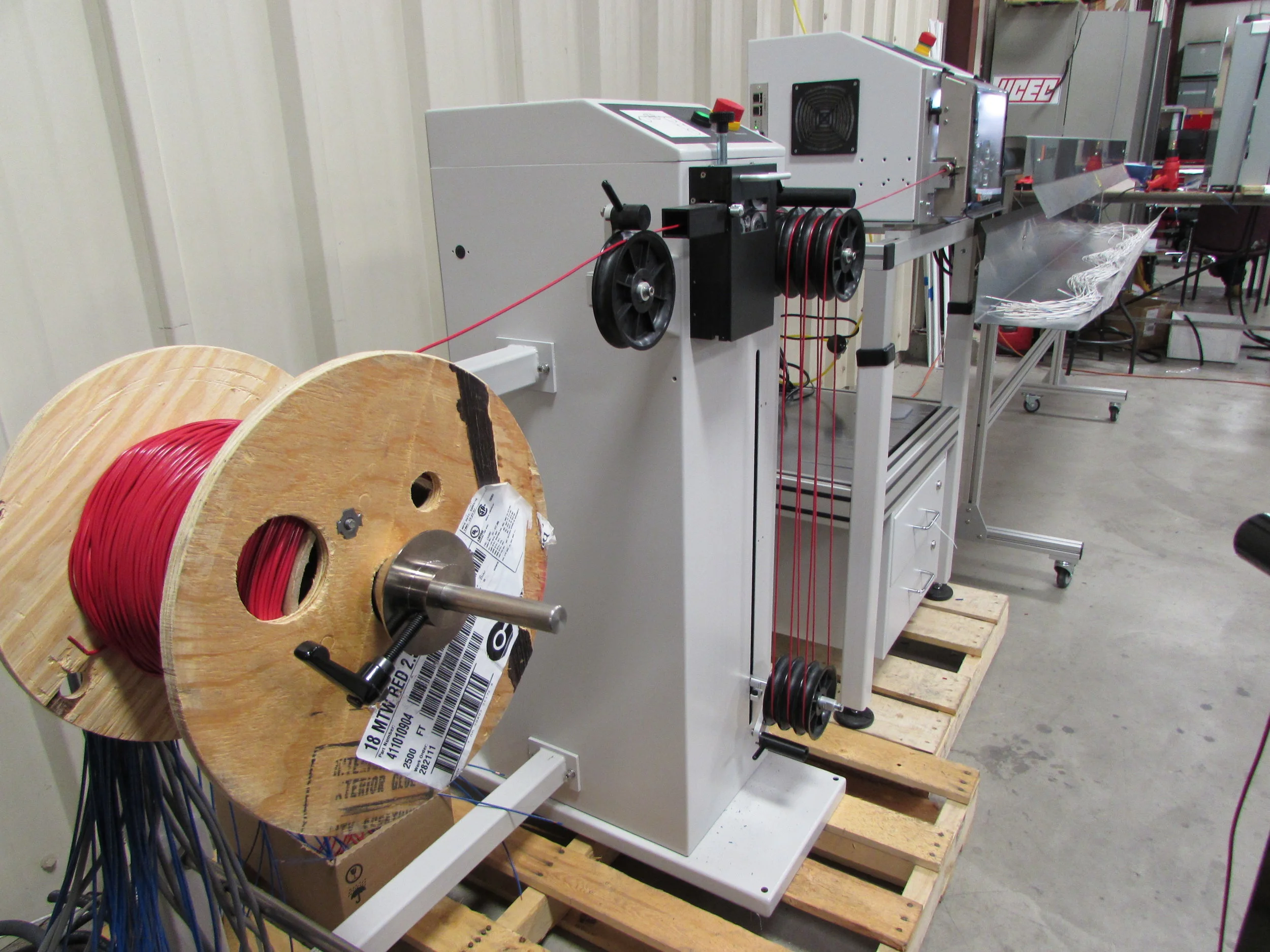

I recently attended a seminar on the Industrial Internet of Things (IIoT). Sponsored by Rexel and Rockwell Automation*, the seminar was attended by folks who work in and design systems for “the connected enterprise.” I ran into several engineering firms we work with, in addition to UCEC customers and vendors. IIoT is a real game changer in our industry with the advantages of reduced costs, faster installation and real-time data.

I enjoy attending technical seminars like this one because you have to stay up to date. If you’re standing still, you’re moving backwards. I never forget that we’re working toward the goal of wiring that first wireless panel.

Some of the topics included:

- Design and implementation practices of IIoT

- Applying smart sensors in the field

- Integrated Motor Control (Ethernet Enabled Motor Control…MCCs, VFDs, etc)

- Collaboration Software and Monitoring Tools

- Protection of rotating equipment

- Automatic code generation techniques for smart devices

One session that was very interesting was on the IO Link, which is the standardized term all over the world for the communication with sensors and actuators. “Old” sensors that our panels hooked up to were fairly simple. They would count cans (for example) and send this information back to the control panel. They could turn things off or on. Pretty simple stuff.

Now, with IIoT, with that same cable, you can send much more information back to the control panel. The new IIoT sensors can tell you that it’s missing something it needs or it is having communication failures. It can tell you if it’s getting dirty or needs maintenance. This predictive maintenance is really helpful for preventing downtime. In the old days, if a sensor shut down, that meant the line was shut down, too, as repair techs tried to isolate the broken sensor and fix it. These days, we can prevent downtime by anticipating maintenance.

Read: How UCEC Prevents Downtime

IIoT is a time saver. Field techs or plant management can fix things when they know they are about to break. They can get ahead of ordering the component. Technical staff can be scheduled proactively instead of reactively.

In the shop, we are starting to see IIoT in the panels that we are assembling and wiring. The new panels are putting money back in our customers’ (or their customers’) pockets due to reduced downtime and access to real-time data.

One great upside to IIoT is that our customers can update their sensors without rewiring the panel. If you have an existing panel system, you can have these new IIoT controllers in the “old” panel.

We’re surfing the wave of new tech in our industry. It’s only going to get more personalized, accessible and data rich. Join us for the ride!

* We’re proud to work with many great vendors. We like to think of ourselves as “Switzerland”—very neutral on who we work with and buy from. All vendors are welcome at UCEC!

Evan is VP of Business Operations at UCEC.

More Content from Evan Coulter

As the calendar winds down and turns over a fresh page, we're taking a look back at 2017's accomplishments. There were many, including: UCEC's new tech projects, our new published case studies, going "green" with wire duct and our launch of new project management software. We promoted team members, traveled to Mexico and some of us ended up on video and online telling the UCEC story (looking at you, Mark!). All in all, it was a year filled with hard work, great projects and continued success for this company that will celebrate 60 years in business in 2018. Thanks for a great 2017, and here's a toast to our leadership who motivate us each and every day at work.