Behind the Craftsmanship of an Industrial Control Panel: Before the Wiring

Editor's note: We kicked off our series this week, "Behind the Craftsmanship of an Industrial Control Panel." You'll hear from various UCEC leaders about the departments that work together to create UCEC's high-quality panels.

By Garrod Massey

I’m happy to lend my hand to the current series, “Behind the Craftsmanship of an Industrial Control Panel.” Since I oversee the wiring side of the shop, naturally my part will be about wiring and testing electrical control panels.

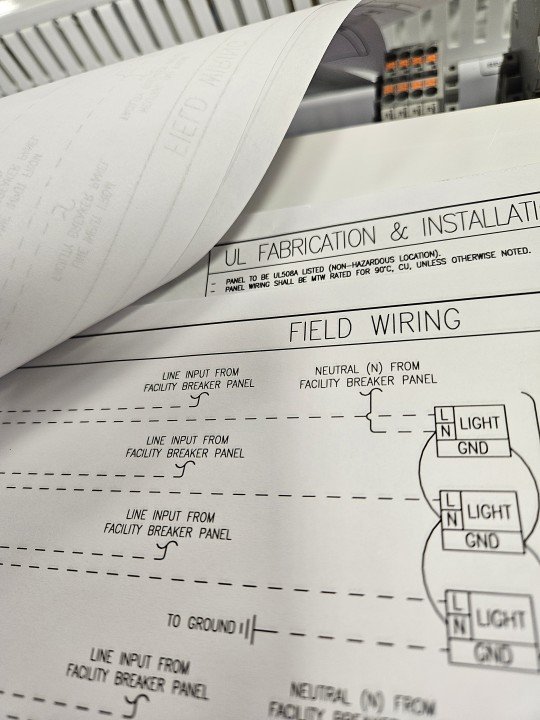

But as I gathered my thoughts, I realized that even before the first wire is pulled, another process takes place. It’s the “translation” of what each customer wants in the wiring specification for their panels.Wiring terminology can be like another language. You see, there’s no “color code” when it comes to wiring our panels. No UL listing tells us where and when to place a wire or what color to make it. Instead, we’ve learned over the years that engineers have preferences. And we do our best to learn those preferences and execute on them when we craft our panels.

For instance, when we bundle wires on doors, we use sticky backs. But some customers want a stud welded to the door instead. Another example is mounting a terminal block: does the engineer want the wires to exit to the left or right side? It’s our job to know this information.

We translate each customer’s preference for wiring practices in several ways. First of all, we maintain a robust library of project photos. We reference this library. Second, we consult the schematic drawing; and finally, we communicate with the engineers by email or phone to get every detail finalized.

We’re not cranking out the same panel on every job. It’s quite the opposite. Every panel we do is customized for the project. We hold our craftsmanship to a high level. I like to think of it as a team effort to finish every panel we create.

Garrod is an Operations Support Manager at UCEC.

UL Certification is critical across multiple sectors, including: Oil & Gas, Chemical Manufacturing, Mining, Pharmaceuticals and Food Processing. Industries where explosive atmospheres are common must prioritize UL Certification to maintain safety and compliance.