Power Circuits vs. Control Circuits in Industrial Panels

In an industrial electrical control panel, there are typically two main types of circuits: power circuits and control circuits. These circuits serve distinct functions and are designed to handle different types of electrical loads and signals. Here's an explanation of the key differences between the two:

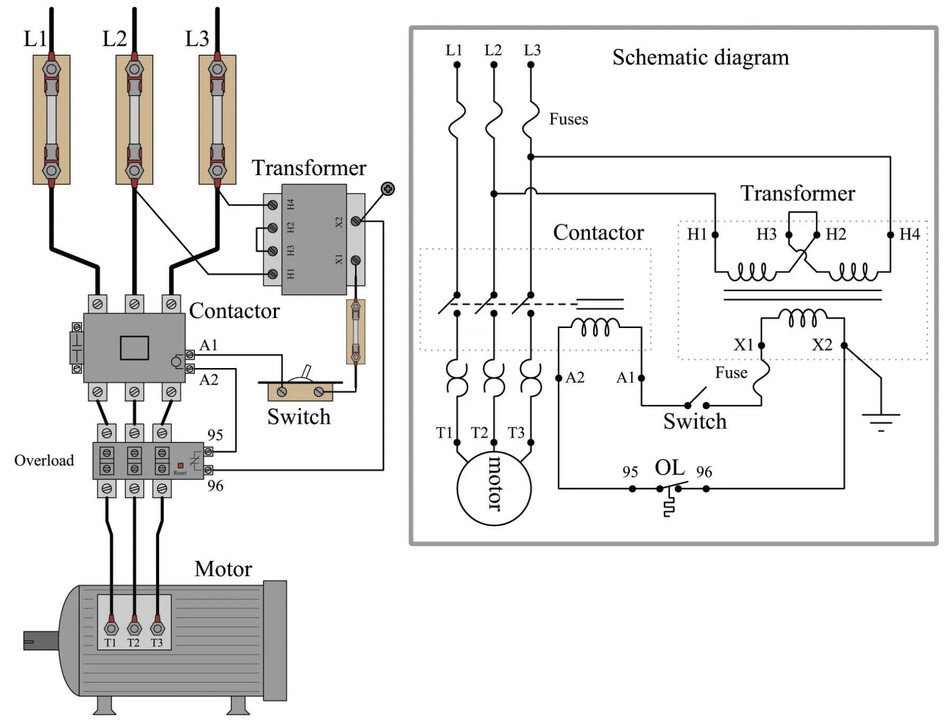

Power Circuit

Function: Power circuits are responsible for carrying electrical power from the source (such as a main electrical supply or a motor starter) to the industrial equipment or loads that require it. These circuits handle the main supply voltage and current needed to operate machinery, motors, heaters, lights, and other high-power devices in an industrial setting.

Voltage and Current: Power circuits carry high voltage and current, which can be hazardous if not properly managed. They are typically at higher voltage levels, such as 120V, 240V, 480V, or higher, and can carry significant current, often in amperes or even kiloamperes (kA).

Wiring: Power circuits use larger conductors and are typically made of materials suitable for high power, such as heavy-duty cables, busbars, or large-gauge wires.

Protection: Power circuits are equipped with protective devices like circuit breakers, fuses, and contactors to ensure safety and control overloads and short circuits.

Control Circuit

Function: Control circuits are responsible for managing the operation and coordination of industrial equipment. They handle low-voltage signals and are used to control the activation, deactivation, and interlocking of various components and devices within the industrial system, such as motors, pumps, valves, and other machinery.

Voltage and Current: Control circuits operate at lower voltages, typically 24VDC, 120VAC, or other low-voltage levels, and carry very low current, usually in milliamperes (mA) or amperes.

Wiring: Control circuits use smaller conductors, such as control wires and cables, and are often connected through relays, contactors, or solid-state devices like transistors and PLCs (Programmable Logic Controllers).

Protection: Control circuits are protected by control circuit protection devices, such as fuses or circuit breakers designed for low-voltage and low-current applications.

Summary

The primary difference between power circuits and control circuits in an industrial electrical control panel is their function, voltage and current levels, wiring, and protective measures. Power circuits are responsible for delivering electrical power to the equipment, operate at high voltage and current levels, and use heavy-duty wiring and protective devices. Control circuits, on the other hand, handle low-voltage signals to control the operation of equipment and use smaller conductors with dedicated protection for their specific requirements.