The Most Important Features of a Properly Designed Industrial Control Panel

Industrial control panels play a pivotal role in the efficient and safe operation of manufacturing and industrial processes. These panels are the nerve centers of a wide range of machinery and systems, ensuring they function as intended while safeguarding personnel and equipment. A properly designed industrial control panel is essential for smooth operations and minimizing downtime. In this article, we'll explore the most crucial features that should be incorporated into a well-designed industrial control panel.

Compliance with Regulatory Standards

The first and foremost feature of a properly designed industrial control panel is compliance with relevant industry and safety standards. In the United States, for example, Underwriters Laboratories (UL) and the National Electrical Code (NEC), and in Europe, the International Electrotechnical Commission (IEC) standards govern the construction and installation of control panels. Compliance ensures safety, reliability, and legality. This includes adhering to guidelines for wire sizing, insulation, component selection, and protection against electrical faults.

Robust Enclosure Design

The control panel's enclosure is a critical component that provides protection against environmental factors, such as dust, moisture, and physical damage. It should be designed to meet the specific needs of the application, whether it's indoors, outdoors, or in a hazardous location. Enclosures must be properly sealed, adequately ventilated, and equipped with cooling systems to maintain an appropriate temperature for the components inside. Ingress protection (IP, NEMA, UL Type) ratings define the level of protection provided against solid objects and liquids, and it's crucial to choose the right rating based on the operating environment.

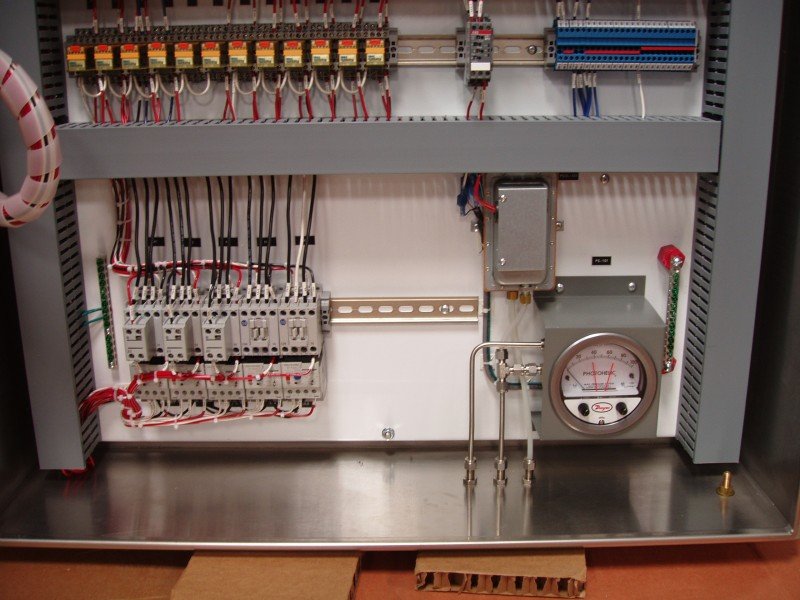

Component Selection and Organization

Selecting the right components is essential to the control panel's performance and longevity. These components include circuit breakers, relays, terminal blocks, contactors, and more. It's vital to choose reliable, quality components from reputable manufacturers. The organization of these components within the panel should be intuitive, following logical wiring schemes and clear labeling for easy maintenance, troubleshooting, and future expansions.

Proper Wiring and Conduit Management

Effective cable management is a hallmark of a well-designed control panel. All wiring should be neatly organized, and the use of color-coded wires and proper cable labeling makes it easier to identify and trace connections. Wiring should follow best practices, with minimal cross-overs and careful consideration of potential electromagnetic interference (EMI) and radio-frequency interference (RFI). Conduit and cable trays should be used as needed to protect and organize the wiring.

Safety Features

Safety is paramount when dealing with industrial control panels. Properly designed panels incorporate features such as emergency stop buttons, interlock mechanisms, and safety relays to ensure the safety of personnel working with or around the equipment. Overcurrent and short-circuit protection devices, like fuses and circuit breakers, are critical for preventing electrical fires and equipment damage. Grounding and bonding should be thoroughly addressed to prevent electrical hazards.

Control and Monitoring System

The control system is the heart of the industrial control panel. It should be designed to provide precise control over the machinery or process it's overseeing. Additionally, a user-friendly Human Machine Interface (HMI) can make it easier for operators to interact with the system. Modern control panels often incorporate programmable logic controllers (PLCs) or microcontrollers for advanced automation, monitoring, and data logging.

Documentation and Maintenance Considerations

A well-documented control panel is easier to understand, troubleshoot, and maintain. Comprehensive documentation should include wiring diagrams, component lists, panel layouts, and operational manuals. Maintenance considerations should encompass planned maintenance schedules, spare parts lists, and a clear understanding of how to access and service the panel safely.

Conclusion

Properly designed industrial control panels are the backbone of modern manufacturing and industrial processes. They ensure the safe, reliable, and efficient operation of machinery and systems. Compliance with regulatory standards, robust enclosure design, component selection, wiring and conduit management, safety features, a well-designed control and monitoring system, and comprehensive documentation are the most critical features of a well-executed control panel. By paying careful attention to these aspects, industries can minimize downtime, reduce the risk of accidents, and enhance productivity.