Electrical Control Panel Innovation, Evolution, and Changes Over 60 Years

Changing Industry: Mapping the Evolution of Control Panels

This year, UCEC is celebrating its 60th year as a control panel shop. Over half a century later, the world’s demand for control panels is still high and the primary function of the panel has remained the same, but almost everything else has undergone some change. Our Vice President takes us through some of the major changes in creating quality control panels at a fair price.

Evolving Control Panel Sizes

I’ve worked at UCEC for 18 years and one of the biggest differences in how control panels are made today is how much smaller all of the components are. Regardless of market, real estate is a finite resource and the size of a panel affects how much room is left in a plant for production. All of the components have been getting smaller, but most notably the brains of the panels, the PLCs, have undergone a drastic decrease in size.

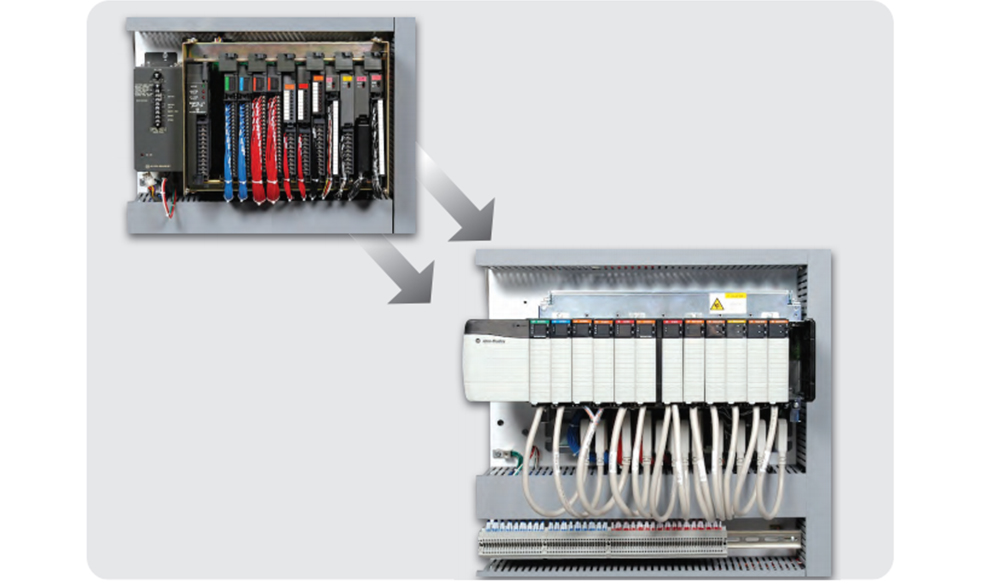

When I started in the panel shop, the Allen-Bradley PLC-5 was king. This PLC was probably 2.5’ tall, a big giant monster sitting in there. Today, ControlLogix, MicroLogix, and CompactLogix PLCs are about a quarter of the size, freeing up a lot of room inside the panel.

Overall, what used to fit in a five-door control panel can now fit into a three or four door panel and this is a trend that’s going to continue.

Size comparison of PLC5 vs. ControlLogix

Improved Control Panel Efficiency

Control panels today are a lot more energy efficient than they were twenty years ago, let alone sixty. Electrical components are becoming much more efficient as technology becomes better. This efficiency is allowing components to run cooler with less energy loss, therefore less heat being released from the components. Being a UL 508A panel shop, we have to stick to strict assembly tolerances. That being said, we are required to follow manufacturer specified air spacing requirements around components, allowing them to properly dissipate heat. Twenty years ago, most panels were controlled with AC power and now it’s DC power. This shift in control voltage means different power consumption. When the power coming into the panel is used more efficiently, the components give off less heat and can then be placed closer together per the safety ratings. Closer components also contribute to the smaller footprint of panels today vs. 60 years ago.

Increased Control Panel Safety

Control Panel Starters: Safety and Size differences over the years

Control panel safety has come a long way. The major increases in safety have resulted from control voltages dropping to 24VDC as well as 95% of components being manufactured “finger safe”. This means that all live parts are either encapsulated or recessed into the part, making it nearly impossible to have an accident. This greatly reduces the risk of shock or injury in the event that an operator happens to touch a live part with their body or tools. The 5% of components that are not built finger safe don't go overlooked. UCEC will fabricate lexan covers to increase the safety of these devices.

Control panels have a lot more arc flash controls today. Arc flash is the light and heat produced from an arc fault, a type of electrical explosion or discharge that results from a low-impedance connection through an electrical system. Up to 77% of all electrical injuries are caused by arc flash incidents. All of our panels are NEC/NFPA 70E/508A compliant which protects against arc flash and makes the panels safer for the operators. Essentially, if someone is opening a panel door to assess a component or troubleshoot an issue they might be having, they can rest assured of their personal safety.

Better Control Panel Communication

Today, Ethernet is the standard communication system for control panels. Before Ethernet control there was no standard, which often required a lot more work. Previous systems included ControlNet, DeviceNet, and DH Plus. This lack of standardization required a lot of different programming as the separate protocols didn’t always interact seamlessly with one another. Many of these protocols are still around, but when a panel is replaced or refurbished, Ethernet is typically what replaces their communication systems.

Wireless panel communication is definitely on the horizon, but there are still a lot of challenges in combating electronic noise. Most plants and facilities that these control panels are being installed in are very electronically “noisy” places which cuts down on the distance wireless communication can travel and the quality of that wireless signal.

Higher Quality Control Panel Fabrication

Not only have the components that go into control panels changed, but so has the way we fabricate them. In the old days, we would lay out each panel by hand, with the tape measure, straight edge and a green marker. Next, we would drill the panels by hand and tap each hole by hand. This was time consuming, not clean and very inefficient.

Thanks to our adoption of new technology, we now do the layouts in AutoCAD, let the Steinhauer do the drilling and use cordless screwdrivers to put in Thread-Forming screws. This is not only more efficient and cleaner for our team, but it provides the customer with a better end product.

Our quality control panels are built to last. The main issue affecting their longevity today is when their components become obsolete because panels are changing at a faster rate now than they have in the past 60 years. Technology is evolving so quickly, some of our panels become outmoded before they don’t run any more. The most common reason a plant may choose to switch to a newer model is due to power efficiency.

We’ve seen a lot of change in our 60 years of operations and at the rate technology is evolving, I anticipate we’ll see a faster rate of change in the near future. The Internet of Things, wireless technology and a continued focus on safety and efficiency are going to continue transforming the control panel world. If you’re looking to start a new panel project or refurbish an old one, contact us today for the latest, state-of-the-art panel build.