What Makes a Quality Control Panel: Three Questions with UCEC’s Garrod Massey

Editor’s Note: We sat down recently to talk with UCEC Vice President Garrod Massey.

Garrod Massey

Why does a panel get UL Listed?

Our UL listings are a big deal at UCEC and something I think about all of the time.

Customers request a UL listing for their panel project for a variety of reasons, but usually it’s because the listing is required by a local municipality. We also build panels to UL standards regardless of the listing requested.

More and more customers are asking for a UL listing, so I think it’s going to become standardized in the future. Many customers know the care we put into our panels, and they know the UL listing will be a good factor in their project.

We train extensively on UL, so we’re immersed in this work every day. It’s hard for many of our customers to keep up with the listing requirements, so it’s easier for them to hand it off to us. And we’re happy to take the lead and make sure the panel is wired to UL’s strict standards– whether the client is making it a requirement r not.

See more about why you should save yourself the trouble, and always buy a UL Certified panel.

Can anyone build a panel?

(Laughs). Can anyone build a panel to our specifications and craftsmanship? No. We build panels carefully and how they should be built—with the end user in mind. When we see some panels from other panel shops, it’s obvious that they made it to be easy on their panel shop, not the end user.

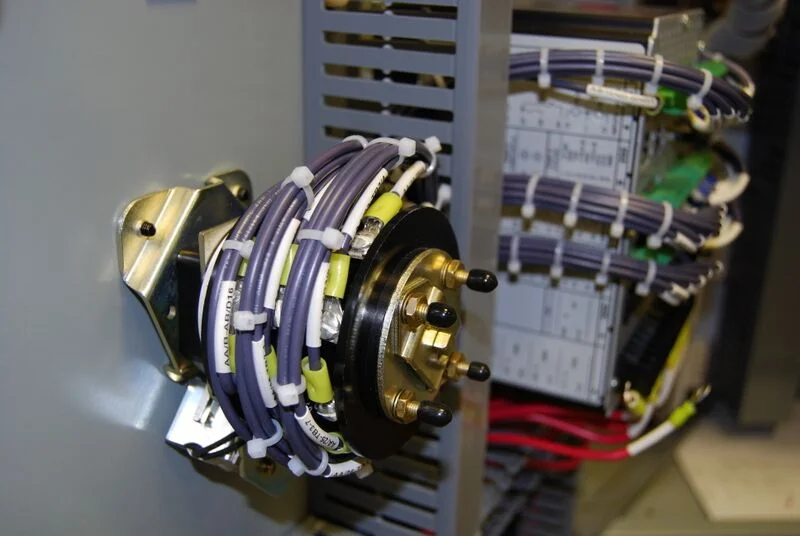

When we work with engineers, each firm has unique preferences and we try to learn them and execute on them when we craft our panels. For instance, when we bundle wires on doors, we use sticky backs. But some customers want a stud welded to the door instead. Another example is mounting a terminal block: does the engineer want the wires to exit to the left or right side? It’s our job to know this information.

A panel project is a blend of engineering, metal fabrication, electrical work and finesse.

Why are UCEC panels the best panels anywhere?

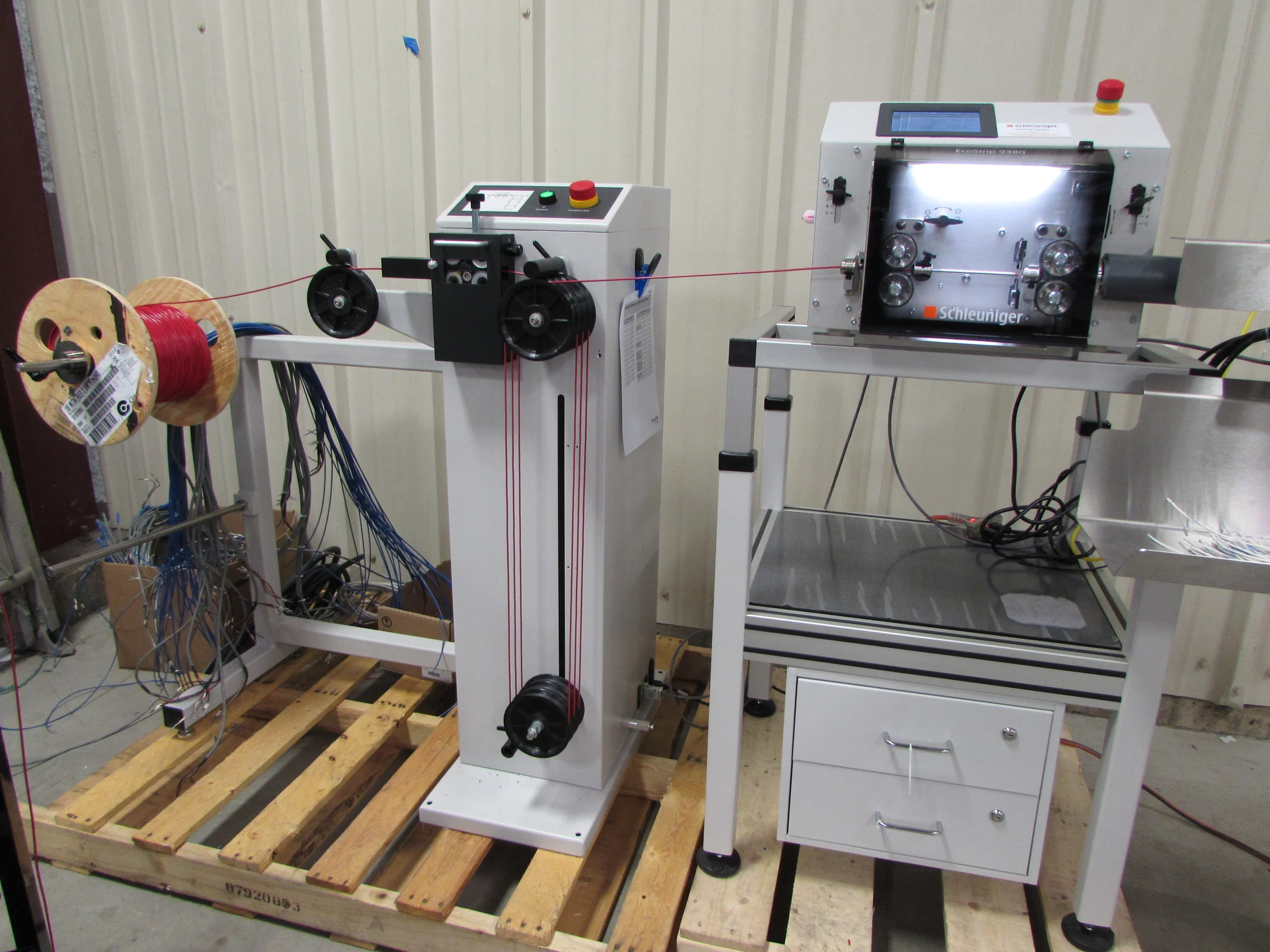

Perfection takes time, and we’ve been in business for more than 60 years. We’ve pretty much seen it all. We stay up-to-date with new technology. We work with many engineers across various industries and in different types of panel locations. We consult with our customers, and when we have a question or a suggestion, we offer our expertise.

The UCEC shop is divided into areas such as Fabrication, Wiring and Quality Control. Everyone is expected to excel in their area. We have to pass each panel project onto the next area, so there is a lot of pride that goes into our work. No one wants to hand off something that will make the next colleague’s job harder.

UCEC has always carved its own path. We’re not competing with anyone except our last project.

There are seven people on our Quoting Team, and between us, we have 140 years of experience! That’s a lot of panels over the years. Even with all of this experience, when a quote comes into UCEC, we approach it like a team. We know our customers need their quotes back quickly.