New Technology Training Camp

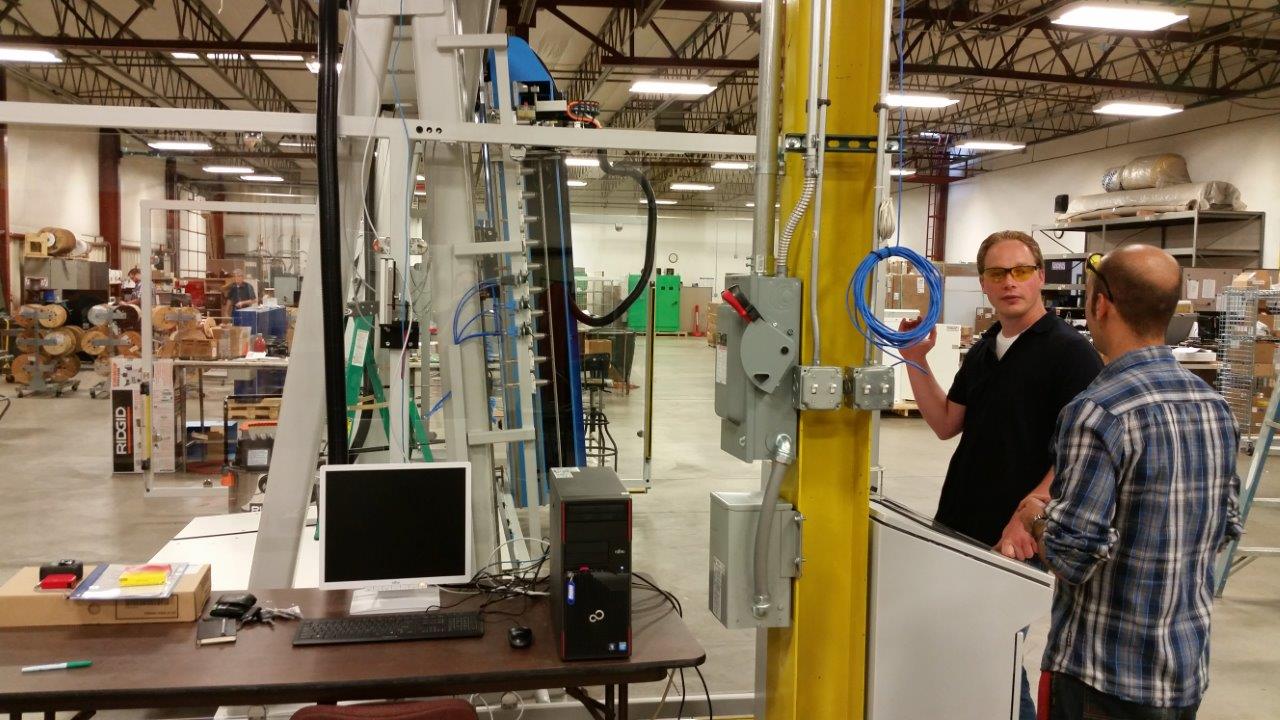

It's training time at UCEC this week. Our panel shop team is receiving an intensive course in how to set up and use our new eCAB ModCenter 80 machine. This piece of German technology will allow our panel shop to complete panel projects quickly and more accurately. The MC80 will shorten the time we lay out and drill holes in the panels. It's the only machine of its kind in the Rocky Mountain region.

The new MC80 machine is equipped with a master control panel and a touchscreen rolling operator console.

The machine is equipped with a vacuum pump which creates a suction for two different purposes: first to keep whatever we are cutting from moving around via suction cups; and second, to remove debris from the cutting process via a suction that surrounds the rotating cutting tool.

Also, the machine has a lubrication spray that coats the cutting surface and cutting tool to keep friction heat to a minimum and prolong the life of the tool.

It's a pleasure getting to know our new MC80 and we're looking forward to bringing the benefits of this new technology to our customers. We think they will be delighted with the best-in-class technology that UCEC is delivering to their custom control panel projects.