Being S.M.A.R.T.

By Evan Coulter

You’ve likely heard of S.M.A.R.T. goals: Specific, Measurable, Achievable, Realistic and Time-bound. This system is a great way to roll out goals in a manner that encourages the organized pursuit of success.

I like to use the S.M.A.R.T. structure with our employees. My goal-setting session isn’t the employee’s “official” review. Rather, my attempt with the system is to check in and see if we are meeting the employee’s needs and if they are meeting our needs. I ask questions such as “What is your goal for the year? What skills do you want to have by the end of the year that you don’t have now?”

This goal-setting session is a mix of the personal and the professional. For instance, a new wiring technician may want to move on from wiring PLC cards to learning how the panels are networked together. This same employee may also need guidance with how to use their vacation time they’ve earned. Many of our younger employees come to us without any experience managing PTO. I personally feel it’s very important that our employees take a trip and come back to us refreshed and renewed. So, with our younger team members, I am going to nudge them into taking a vacation somewhere that matters to them.

I replace the “R” in “Realistic” with “Responsible Party.” This is the person to whom the employee will report their goal actions. The responsible party can be their supervisor or someone else at the company. With this method, we’re checking in with the employee instead of leaving them to figure out everything on their own.

Using the S.M.A.R.T. method is a great way to keep the employer-employee relationship supportive and engaged. Our employees are our greatest asset, and we want them to stay with UCEC happily for years to come.

Evan is Vice President of Business Operations for UCEC.

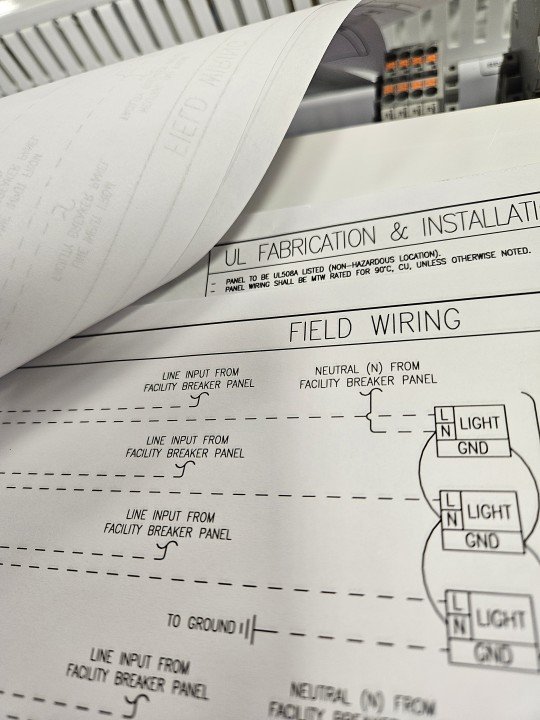

UL Certification is critical across multiple sectors, including: Oil & Gas, Chemical Manufacturing, Mining, Pharmaceuticals and Food Processing. Industries where explosive atmospheres are common must prioritize UL Certification to maintain safety and compliance.